| Surface Finishing Services Metal finishing or metal finishes is the process of utilizing different techniques to alter the surface of an object, for improving the appearance and properties like corrosion resistance, tarnish resistance, chemical resistance, wear resistance, and hardness, modifying electrical conductivity, removing burrs or applying specific colors to the machined components. It usually through adding a layer of metal or non-metal coating on the exterior of a metallic workpiece, which can also clean the part at the same time. The metal surface finishing services commonly applied on various metal parts made of aluminum, stainless steel, brass and more materials.

|

Benefits of Metal Finishing Process The functions of metal surface treatment can be summarized as follows: – Optimize grain structure – Improve physical properties |  |

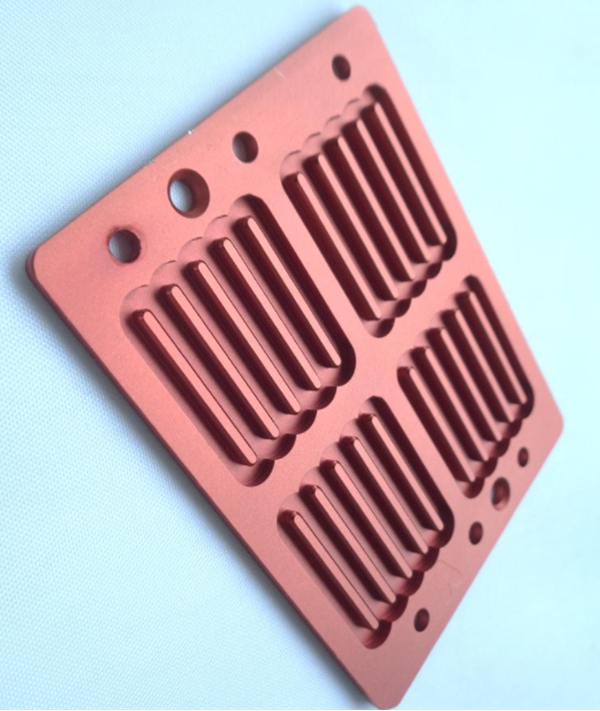

Metal Surface Finishing Services Available at RIGID 1. Anodizing (Anodized) An electrolytic passivation process of forming a thin layer of metal oxide on the exterior of CNC machined parts to increase the thickness of the natural oxide layer, protect the metal, add various colors, as well as improve corrosion and abrasion resistance. Aluminum is the most widely anodized material, and the advantages of anodized aluminum components are well known, but many other metals can undergo the process, such as stainless steel, copper, titanium, zinc, and magnesium. 2. Passivation A common chemical surface treatment method mostly for steel and stainless steel, to use a light coat of protective material to create a shell for enhancing the corrosion resistance or reducing the chemical reactivity. Passivation of stainless steel removes free iron and ferrous contaminants on metal surface with an acid solution to prevent rust. 3. Plating (Electroplating) The process of using an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode, to change the properties of the metal surface or build up thickness for undersized parts. Chrome plating, nickel plating and more are often applied at RIGID. 4. Painting The process of spraying paint, pigment, or color to a solid surface as a colored protective layer and can be done on metal or non-metal CNC machined components of any shapes, usually applied on aluminum, stainless steel and steel alloy parts. The purpose is to improve aesthetic appearance and prevent corrosion or oxidation. 5. Black Oxide (Hot Blackening) The technique also known as blackening, or gun bluing, a chemical process of forming a black conversion coating on stainless steel, copper and copper-based alloys, zinc, powdered metals, silver solder, and ferrous materials, the black oxide coating can improve corrosion resistance and minimize light reflection. 6. Polishing Polishing, also known as buffing, a process of rubbing the surface of parts or utilizing a chemical action to produce a smooth and shiny surface, make the surface get significant specular reflection or reduce diffuse reflection in some materials. 7. Powder Coating The process of placing a functional and decorative finish, which is applied as a free-flowing, dry powder, employs electrostatically and then cured under heat, to create a hard finish that is tougher than conventional paint. The main applications including household appliances, aluminum extrusions, drum hardware, automobile, motorcycle, and bicycle parts. 8. Satin Finish Apply a luster between the dull, non-shiny finish of matt materials and the bright and shiny finish of glossy finish. The visual effect is related to the lighting of the environment, satin metal finish is reflective, flat and glossy. 9. Abrasive blasting (Sandblasting) The operation of propelling a stream of abrasive material composed of high-velocity sand-sizes particles against the metal surface under high pressure with blast equipment like air pressure system, to remove surface contaminants, clean metals or increase a texture, then change the smoothness or roughness of surface. 10. Conversion coating It is also known as chromate conversion, the coating is used for metals converted to a protective layer through the chemical or electrochemical processes, primarily used as a corrosion inhibitor, decorative finish, or to retain electrical conductivity.

| |