Metal Stamping Service

|  |

Our manufacturing process includes the following techniques based on your specifications: · Punching · Blanking · Coining · Bending · Flanging · Drawing · Embossing · Curling · Piercing

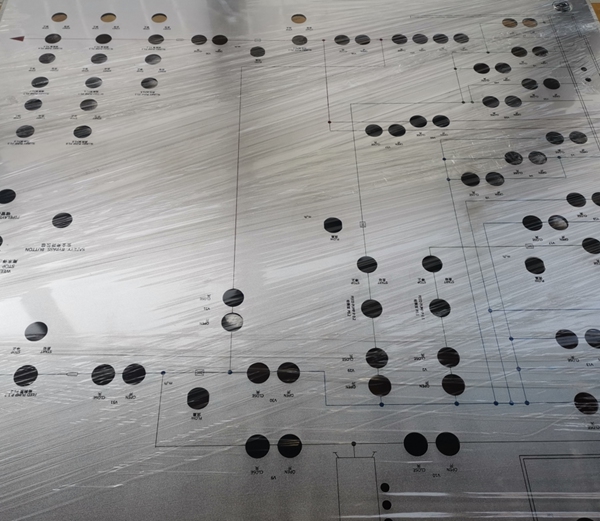

| What is Metal Stamping? Metal stamping uses a stamping press to shape flat sheet metal, also called stamping blanks. The tool and die surface use various techniques to work the metal, depending on the parts you need,designing a stamping project uses CAD/CAM technology to make precise, identical parts every time. It takes patience and requires attention to detail to ensure precision and that all the final pieces fit together as intended. |

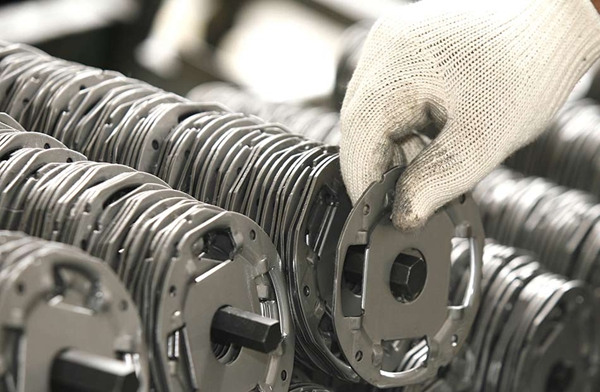

Types of Metal Stamping Metal stamping projects use various techniques to achieve the right shape, size, consistency, and speed. While each type has its advantages, they all work for different purposes and industries according to the pieces they produce. Progressive With progressive stamping, we move strip metal through a progressive stamping press, where it passes from one station to the next. Each station performs a specific function, including punching, bending, and cutting the metal. Often, progressive stamping requires multiple machines, especially when a project involves complex parts. Progressive stamping offers the advantages of a quick turnaround and creating repeated, uniform pieces. It also has the lowest labor cost of each stamping type. Fourslide Fourslide stamping uses four tools, with each one bending the metal into the desired shape simultaneously. Fourslide stamping simplifies the creation of complex parts. While it doesn’t create pieces with as much uniformity as progressive stamping, it makes changing or adjusting the design easier when a project requires many parts with different bends. Deep Draw Deep drawing is a technique where we use a punch to feed a blank into a die. It works best for projects where a customer needs products of different diameters, often in the automotive or aerospace industries. Deep drawing uses fewer raw materials than other stamping processes. It also works well for producing less complicated pieces at high volume.

| |

We Offer Custom Metal Stamping Services Most companies have different requirements, even within the same industry. That’s why we offer custom metal stamping, no matter your needs, we will work to understand your company’s specifications and create a design and die to give you the product you want. We even offer services that go beyond making a custom metal stamping, including:

· Plating · Heat-treating · E-coating · Screw insertion · Stress relieving · Reel-to-reel · Tape and reel · Pick and place |  |

| When you choose RIGID for metal fabrication services, you work with a team of dedicated professionals who care about your business. Our exceptional quality control measures mean we uphold the highest standards. We won’t declare the job finished until you’re satisfied, we communicate with you from design to product completion to ensure you feel as confident in our products as we do. Contact RIGID today to learn how we can fabricate the metal products you need for your company.

|