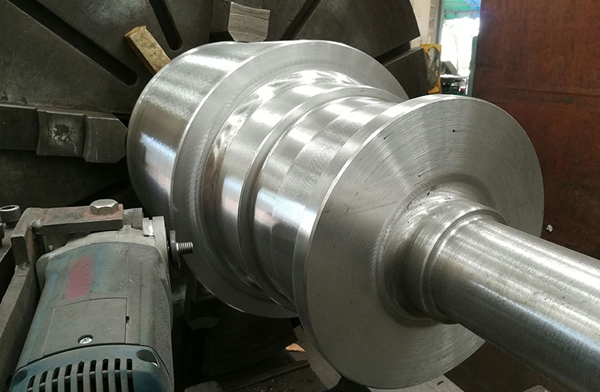

Centrifugal Casting Centrifugal casting or as it’s also known, rotocasting, is the process of creating cylindrical parts using gravity or pressure to fill a rotating mold. Machines used to rotocast are horizontal if long cylinders are being cast or vertical if rings are being cast. Molds can be made of steel, cast iron, or graphite. To begin the process, the walls of the mold are coated and baked with a refractory ceramic coating to prevent sticking before the mold is then rotated at high speeds.

|  |

| The speeds at which the mold rotates are typically between 300-3000 RPM. Molten metal is then poured into the mold as it’s rotating, and centrifugal forces move the metal into the mold walls evenly. The mold continues to rotate as the metal cools from the outer edge inward. After the entire part is cooled, the mold stops rotating and the piece is removed. If a smooth surface is required, impurities that have been pushed to the inner diameter are removed via machining or sandblasting.

|

Advantages/Disadvantages Pieces made from centrifugal casting can be tailored to the specific needs of the part with any length, thickness, or diameter without a need for cores. Parts have rotational symmetry from gravity without any seams and can be very large in size. The production cost is low as molds can be reused for parts of varying wall thickness and labor costs are low. Centrifugal casting is typically used to create stock materials and may not be a good solution for more specifically shaped parts. Parts made are limited to cylindrical shapes and long lead times are possible.

|  |

| Applications Centrifugal casting or rotocasting can be employed to produce various types of products, depending on the material used. It was first popularized to make steel train wheels. Pipes are made from concrete or steel, engine sleeves and cylinder liners are made from various metals, and television and telescope parts are made from glass, all using centrifugal casting. Industries using this technique include agriculture, industrial manufacturing, transportation, and aerospace including aircraft and rockets.

|