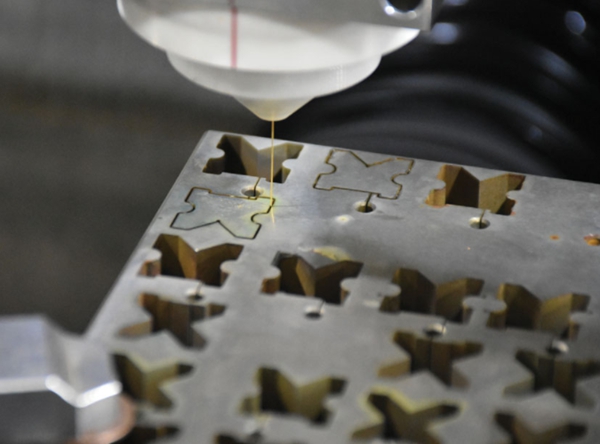

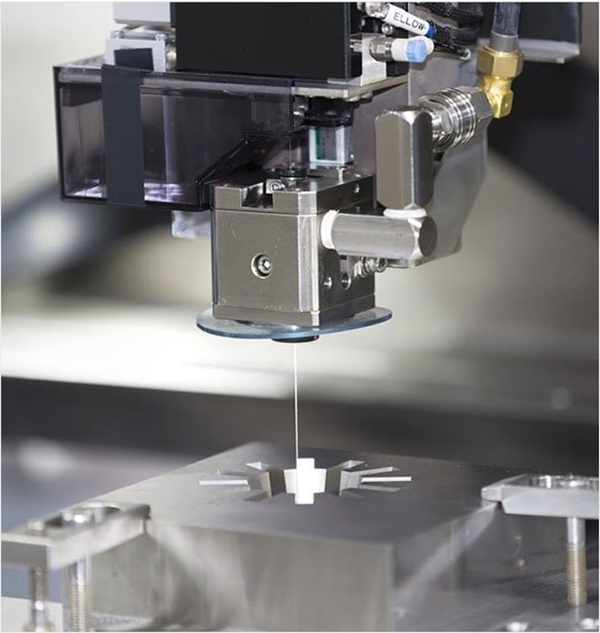

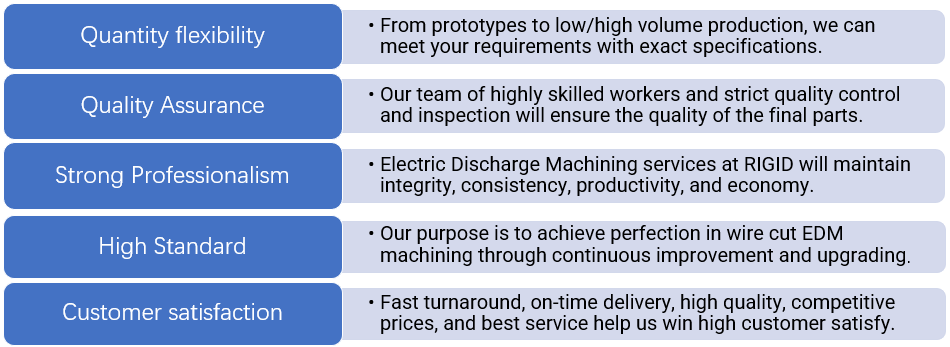

Wire EDM Machining Services RIGID is a specialist that can fabricate industrial parts and custom machined parts using a wide variety of manufacturing techniques. With Wire EDM Machining Services at RIGID, you can get your wire EDM parts in a much more accurate and fast way, compared to conventional machining. Our newest wire EDM machines can meet your needs of high volume while maintaining high repeatability, top quality and tight tolerance. Over the past years, we have earned a good reputation for producing custom parts with reasonable pricing and on-time delivery, Our EDM services offer experience and excellence in all types of EDM machining, welcome to submit an inquiry online. |  |

Advantage of RIGID Wire EDM Machining Services  | |

Benefits of Wire Cut EDM · Avoid damage to small workpieces like conventional machining · Ideal for processing delicate, hard, exotic or weak materials · Suitable for situations requiring low levels of residual stress · Eliminates the need for post-machining or heat treatment · Reduces the possibility of surface distortion · Achieve a burr-free surface and edge finish · Minimizes unproductive downtime and fast turnaround |  |

|

The EDM wire cutting process has become a popular choice for a wide range of industries. The wire EDM can cut any conductive materials including aluminum, brass, steel, titanium, superalloys and other alloys to produce machine parts, components, logos and other metal parts easily. Typically, the electrodes for EDM cutting are made of copper or graphite. |